The company is oriented towards constant improvement and striving for the delicate balance between form and function. These aspects become luminaires and solutions that balance remarkable lighting performance with timeless aesthetics. Performance, beauty, ease of installation and durability are objectives established at the initial product concept and intellectually carried through every design phase, paying particular attention to even the smallest construction detail.

All products are entirely designed in Italy, Germany and Belgium.

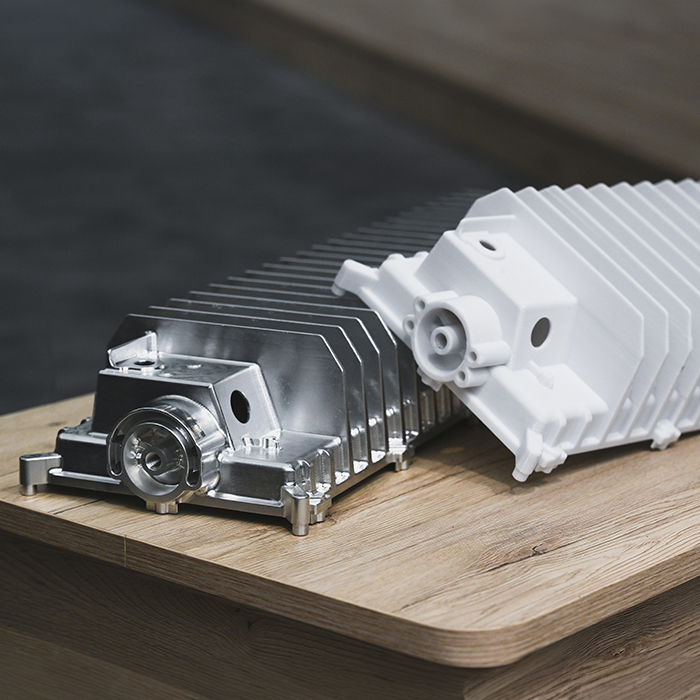

The group's technical offices for product development, design, 3D modelling, thermal simulation and study of fluid dynamics, and optics development all use the latest generation of professional software.

Management software is also used in which all the technical information is reported. These tools make it possible to optimize some phases of the general project management process, improving the broad productivity indices of the company.

The R&D department is equipped with modern 3D printers that can quickly produce a prototype of the designed part, reducing product development times.

Through continuous training, highly competent staff, and instrumentation supplied in its laboratories, the company can now independently perform almost all of the tests required by national and international regulations.

All lighting fixtures manufactured must comply with the strictest safety, quality, and durability regulations. To this end, the company has invested in internal laboratories that operate according to the international standard ISO 17025.

The laboratories are accredited with CTF STAGE 2 (Customers' Testing Facilities - Stage 2) certifications issued by IMQ and VDE.

They produce and certify the technical documentation necessary for the issue of the European ENEC certification.

The same laboratories are WTDP (Witness Test Data Program), qualified to conduct tests according to American standards (UL) to obtain product certification.

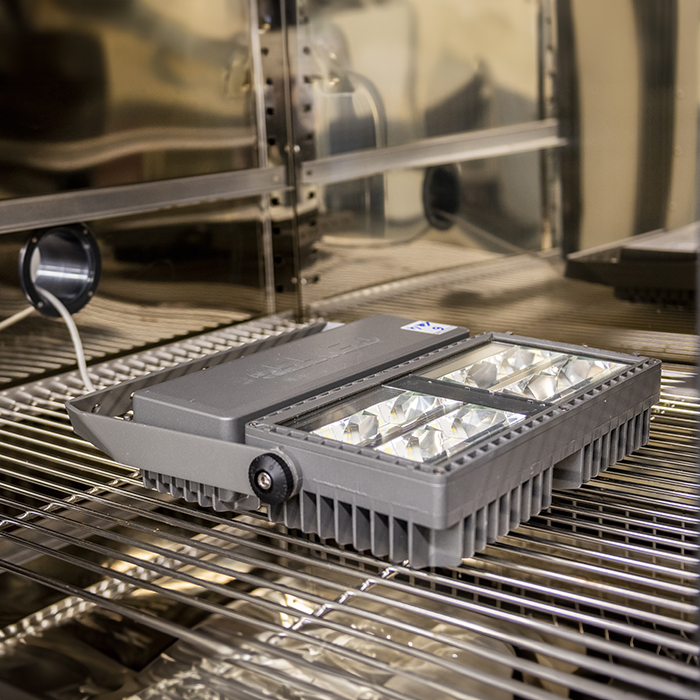

Within the laboratories, temperatures, electrical resistance, electrical insulation, mechanical resistance, protection against the entry of solids and liquids, electromagnetic compatibility and photometric distribution are checked to obtain a safe and efficient product.

Today, the Group has laboratories for electrical safety tests, photometric chambers with proprietary photogoniometers, integrating spheres, measuring optical flicker and stroboscopic effect, climatic chamber, salt spray test chamber and laboratories for electromagnetic compatibility tests.

The constant commitment to improving product quality and service has led the comapany to be certified by a quality system that complies with the ISO 9001-2015 standard for the whole production cycle, from design and production activities to logistics and marketing of its products.

All testing activities are supervised once a year by the Official Certification Bodies (IMQ S.p.A. and UL). The laboratories are recognized by IMQ and VDE according to the CTFs STAGE 2 (Customers’ Testing Facilities) procedures that release the ENEC label in compliance with the following standards:

IEC/EN 60598-1

Luminaires

IEC/EN 60598-2-1

Luminaires - Part 2-1: Particular requirements – Specification for fixed general purpose luminaires

IEC/EN 60598-2-2

Luminaires - Part 2-2: Particular requirements – Recessed luminaires

IEC/EN 60598-2-3

Luminaires - Part 2-3: Particular requirements –Luminaires for road and street lighting

IEC/EN 60598-2-4

Luminaires - Part 2-4: Particular requirements – Portable general purpose luminaires

IEC/EN 60598-2-5

Luminaires - Part 2-5: Floodlights

IEC/EN 60598-2-7

Luminaires - Part 2-7: Particular requirements – Portable luminaires for garden use

IEC/EN 60598-2-13

Luminaires - Part 2-13: Particular requirements - Ground recessed luminaires

IEC/EN 6598-2-18

Luminaires - Part 2-18: Particular requirements – Luminaries for swimming pools and similar applications

IEC/EN 62031

LED modules for general lighting - Safety specifications

Furthermore, the laboratories are recognized by UL according to the WTDP (Witness Test Data Program) for the release of the UL label in compliance with the following standards:

UL 1598

Luminaires

CSA C22.2 NO 250.0-08

Luminaires

UL 8750

Standard for Light Emitting Diode (LED) Equipment for Use in Lighting Products

CSA C22.2 NO 250.13-12

Light Emitting Diode (LED) Equipment for Lighting Applications

Within the laboratories, there is also an outfitted room (with the best EMI Receivers) for electromagnetic compatibility measurements and to ensure that the products are in compliance with the most important industry standards such as:

CISPR 15

Limits and methods of measurement of radio disturbance characteristics of electrical lighting and similar equipment

EN 55015

European Limits and methods of measurement of radio disturbance characteristics of electrical lighting and similar equipment

Considerable investments have also been made in photometric laboratories, which have led to UL recognition to be able to operate in accordance with the UNI EN 13032 standard.

They are climate controlled at 25°C and equipped with various types of goniophotometers (T2 and Type C), spectroradiometers, and Data Logger Multimeters which are capable of detecting luminous flow parameters, electrical parameters, the temperature and all of the colorimetry characteristics (CRI – CCT – Chromaticity coordinates) as described in the reference standards listed below.

Data found are collected and managed by a software that delivers the comprehensive photometric and colorimetric survey.

Data measurements and processing are collected in compliance with the following standards:

UNI EN 13032-1

Light and Lighting –Measurement and presentation of photometric data of lamps and luminaries Part 1: Measurement and file format.

UNI EN 13032-4

Light and lighting. Measurement and presentation of photometric data of lamps and luminaires. Part 4: LED lamps, modules and luminaires.

IES LM-79-08

Approved method for the Electrical and Photometric Measurements of Solid-State Lighting Products.

All products are subject to a vast number of accurate checks directly in the production line. Checks are done with control instruments that are checked and managed by the quality system procedure jointly with the indications reported on the “Minimum Values for Electrical Tests” List of the IEC/EN 60598-1 – Luminaires standard. This ensures the reliability and the compliance with security and performance of the product the Client expects.

All products which are subject to European Directive 2014/35/EU bear the mark CE.

The internal laboratory operates following the UNI EN ISO 17025:2005 standard, which allows PERFORMANCE iN LIGHTING to conduct all of the safety tests for its products. This guarantees the compliance of all products with the current European and extra-European standards.

The ENEC certified lighting fixtures are approved by a third-party certification body and comply with the European electrical safety standards. Companies that offer ENEC products apply a quality system in compliance with UNI EN ISO 9001.

The RCM Mark "Regulatory Compliance Mark", certifies that each individual electrical and electronic product complies with the mandatory safety requirements in Australia and New Zealand such as the electrical safety and electromagnetic compatibility.

The VDE mark documents the safety and conformity to standards of an electrical product with regard to electrical, mechanical, thermal, toxic and other hazards. It is awarded exclusively by the VDE test and certification institute (VDE-PZI). A manufacturer may only provide its products with the VDE mark after checking and issuing of a corresponding certificate.

The EAC mark certifies the conformity of the products with the regulations of the Eurasian customs' area; the mark allows the access to the marketplace of Russia, Belarus, Armenia, Kazakhstan, Kyrgyzstan.

The concept of limited natural resources is given much consideration by the Group during product development.

The design choices, the entire production cycle up to packaging, transport, and all stages of the life of the fixtures placed on the market, including their recycling, aim to reduce potential environmental impacts.

The Group uses components and materials to save energy and respect the environment.

Intelligent control technologies are used, such as sensors that detect daylight and movement, software and electronic components for controlling products and their sources to obtain significant energy savings.

Furthermore, specially designed high-performance reflectors or lenses allow for optimal distribution of light where it is needed, avoiding waste and loss.

The combination of efficient ballasts, optoelectronic light sources, intelligent sensors and highly complex reflectors results in durable, energy-efficient products with respect for the environment.

The company is registereded as a manufacturer with the German waste electricalic equipment register EAR, in implementation of Europeanop Directive 2002/96/EC on Waste Electrical and Electronicon Equipment (WEEE), under the following number: WEEE-Reg. No. DE 27756601 All electric and electronic equipment brought into circulation by the company is marked with the “crossed-out dustbin” symbol with a bar denoting the limit date for putting into circulation.

To our knowledge, our products contain no substances in concentrations or applications the putting into circulation of which in products is forbidden in accordance with the applicable requirements of Directive 2002/95/EC (RoHS).

An environmental officer constantly examines further improvements, and constant staff training courses round off the complete catalogue of measures.

The company is a member of the ECOLIGHT consortium for the recycling of lighting fixtures. ECOLIGHT brings together over 1,700 companies and ensures the management and disposal of WEEE, exhausted batteries and accumulators, and end-of-life photovoltaic modules.

New European directives on ecodesign and energy labelling of light sources for more sustainable lighting.

The European Community has set essential objectives that will lead to significant energy savings by 2030 and an increasingly diminished environmental impact by introducing the new UE 2019/2020 SRL (Ecodesign) and UE 2019/2015 ELR (Energy Labelling) regulations.

SRL REGULATION (Single Light Regulation UE 2019/2020 Ecodesign)

The Group designs and develops its lighting fixtures following the regulations, focusing on the environment and energy sustainability.

All the information required by the regulation is available on the free access website and product instruction sheets.

ELR REGULATION (Energy Labelling Regulation UE 2019/2015)

The company guarantees the registration of the light fixtures of its design and development in the EPREL database following the regulations.

Our company has always been focused on important issues such as environmental protection, energy saving and the well-being of people. The design and development of our products are inspired by these themes every day.

A new collaboration starts with Agenzia CasaClima, an independent public certification body in South Tyrol (I), which managed to create its own certification protocol not only for residential construction, but also in the field of public lighting, wineries, schools, factories and much more. Over the years, it has become a protocol national, also known in Austria and Germany. PERFORMANCE iN LIGHTING becomes the partner in the field of artificial lighting, providing training and consultancy regarding energy savings, smart lighting management, regulations, well-being and visual comfort.