Valor de fluxo meramente teórico: o LED é alimentado por uma fração de segundo e fotometrado a frio, condição na qual gera o máximo fluxo possível.

Valor nominal do fluxo mais próximo da realidade: o LED (ao ar livre, não montado em nenhum aparelho) fotometrado durante o funcionamento normal, a uma determinada corrente, e mantido a uma temperatura de junção de 85°C.

A verdadeira “quantidade de luz” gerada pelo aparelho, ou seja, o valor real de fluxo emitido pelo produto nas condições de uso normais.

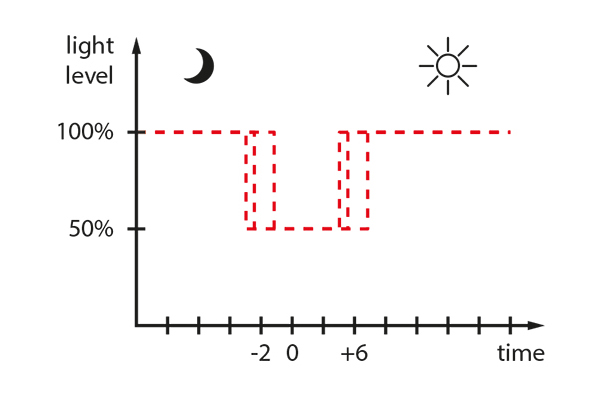

The fixtures equipped with RPA (automatic power reducer) power supply feature a standalone flow regulator since no additional wiring is required and the dimming profiles (up to five) are pre-programmed in relation to “virtual midnight”, in other words, the intermediate time between the switching on and switching off of the fixtures, calculated during the first three days the system is in operation.

Example: let’s suppose that, during a certain period of the year, a system is on from 5:00 pm to 6:00 am the following day for a total of 13 hours. The virtual midnight will coincide with 11:30 pm (13 hours ÷ 2 = 6.5 hours, therefore 5:00 pm + 6.5 hours = 11:30 pm). The Performance iN Lighting factory setting provides 50% dimming from two hours before to six hours after virtual midnight. Considering these parameters, the fixtures will be dimmed 50% from 9:30 pm (11:30 pm + 2 hours) to 5:30 am (11:30 pm + 6 hours) on the following day.

Virtual midnight is periodically updated to adapt to the seasonal changes of how long day and night last, allowing the system to be switched on and off with a twilight switch.

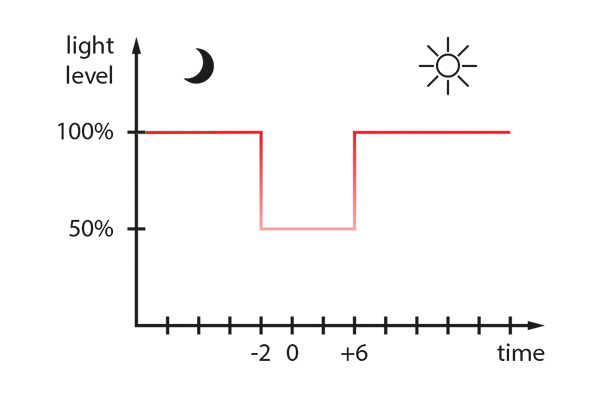

The fixtures equipped with RPP (power reduction with pilot command) power supply have a feature which, using dedicated wiring (the “pilot wire”), allows the flow to be reduced to a pre-programmed level (the factory setting is 50%).

Applying mains voltage to the pilot wire, the fixture is dimmed to the preset value, otherwise it operates at 100% of the luminous flow. By changing the fixture’s programming, this operating logic can be inverted. The product will operate at 100% when the pilot wire is powered and dimmed when it is not.

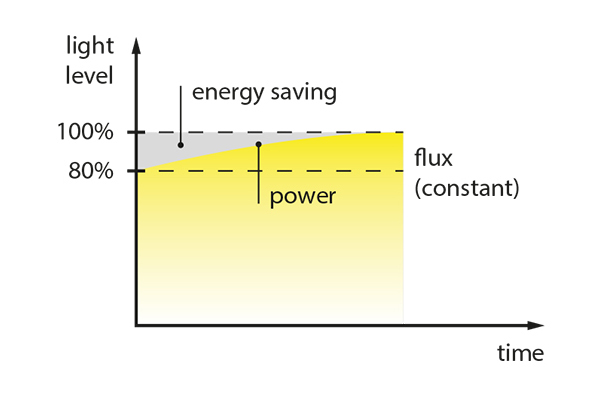

Fixtures equipped with CLO (Constant Light Output) power supply have a feature that maintains the flow constant for the entire life of the system. In fact, like all lighting sources, LED undergo a deterioration in performance that must be considered in the maintenance factor calculation. This means that the fixtures must be used with a flow (and therefore consumption) that is initially greater, since the luminous levels must be guaranteed for the entire life of the system.

For example, in a fixture with a flow deterioration of L80, the CLO will be configured so that the flow is reduced to 80% of the rated value and maintained constant, thanks to the progressive increase of the LED power supply voltage to compensate for the performance deterioration. This implies that a fixture with CLO will always operate with a flow lower than the rated value, which typically coincides with the end-of-life value.

By using products with CLO, since there is no flow deterioration, a greater maintenance coefficient can be used, thereby achieving energy savings.

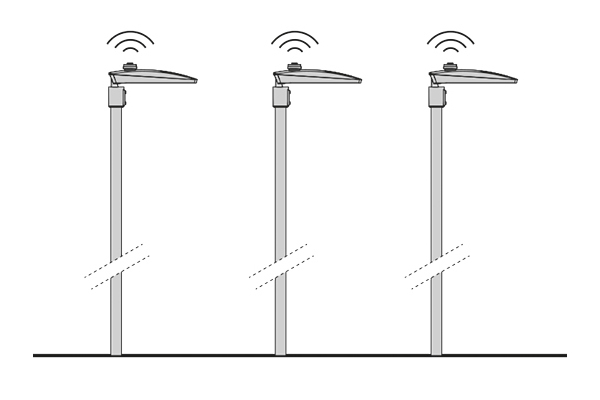

In some installations, the system may need to be managed centrally to modify the dimming profiles, create personalised scenes in relation to the technical lighting requirements or carry out diagnostics on the individual light points. To satisfy these needs, fixtures are available in DALI 1-10V version, or equipped with NEMA or Zhaga Book 18 socket. Performance iN Lighting can also assess the installation inside its fixtures of remote management modules (Wi-Fi, power line communication) based on the customer’s needs.

For many years the Color Rendering Index (also called CRI, colour rendering index, or Ra, average rendering) has been used to describe the ability of a light source to faithfully return the colours of an object concerning a reference source. Several measurement systems are available today, under definition or already approved internationally: Color Render Index (CRI), Color Quality Scale (CQS), Gamut Area Index (GAI), TM-30, American method of IES (Illuminating Engineering Society), CIE 224: 2017 Color Fidelity Index. All these metric systems speak about the human perceptive system directly and no through a television camera.

The Television Lighting Consistency Index (TLCI) tries to solve these problems by providing a specific colour rendering metric for video cameras like how the CRI or TM-30 works with human vision. Alongside the positive aspects of long life and energy savings, LED light sources, due to their spectral emission, can produce a different representation of the colours for the reality of the cameras, thus forcing the television producers to devote a lot of time and money in post-production. In 2012 EBU (European Broadcasting Union) released TLCI-2012 protocol which, although not yet an international standard, has already been adopted and used by all the primary video camera and display manufacturers and by the significant producers of film and television content in the world. The TLCI is a useful tool for lighting equipment manufacturers who want to design luminaires compatible with television demands.

The Television Luminaire Matching Factor (TLMF) is instead a valid tool for professionals who wish to understand how different sources mate and mix before they even carry out lighting designs when it would be too late to remedy any problems. The EBU guidelines define, in the TLMF-2013 protocol, a single scale of evaluation of the chromatic quality of cinematographic images, to which a different weight is attributed depending on whether it is material intended for a television production. Consult PERFORMANCE iN LIGHTING pre-sales service for specific information on your project.

The circumstances that produce the “flicker” phenomenon vary according to the modulations of the light source and derivatives, the frequency of alternating voltage and the frame rate of the camera. The flicker distracts and damages the viewer’s experience. Therefore, it needs to be eliminated where possible. Many institutions try to understand and synthesise this concept. Today in the definition of the TEMPORAL LIGHTING ARTIFACTS (TLA) in which they are defined, through CIE TN (Technical Note) IEC / TR 61547-1 he concept of flicker, stroboscopic and “phantom array”.

Accordingly, the flicker effect is a visible optical stimulus in the absence of eye movement in a static environment. The Flicker Factor (FF) refers specifically to the number of light modulations expressed as a percentage deriving as a ratio multiplied by 100 per cent between the maximum illumination (Emax) subtracted from the minimum illuminance (Emin) and the sum between the same Emax and Emin. Therefore, FF is a percentage number derived from a real measurement on the lighting system. UEFA 2016 standards define FF in three levels of competition to be verified at a standardised height and degrees plan.

When testing professional illumination for stadiums and arenas, it is necessary to establish the type of operating lighting system. Especially LED lighting devices, where FF depends on the type of LED power supply used, not intrinsically produce FF but reproduce faithfully the shape of the wave that arrives from the supply compartment which in this case derives from the type of current driving. A Light Flicker Meter, available on the market, is necessary to measure this parameter after luminaires installation and aiming.

«L» Com o parâmetro “L”, determina-se a percentagem de deterioração do fluxo luminoso referido às horas de funcionamento úteis.

«B» O parâmetro “B” indica a percentagem dos leds que não manterão as características de emissão luminosa determinada pelo parâmetro “L”, então indica a percentagem dos led que produzem menos luz, mas que não apagarão completamente.

PERFORMANCE iN LIGHTING exprime B10 valor sinónimo de componentes eletrónicos de qualidade primária ao considerar incluídos os valores técnicos C e F, alinhando-se às tendências iluminotécnicas do setor.

«C» Indica o valor percentual que representa a quantidade de díodos que terão parado de funcionar após o valor de horas de funcionamento, expresso em milhares, determinado pelo fabricante do aparelho.

«F» Indica a percentagem da avaria ou imperfeição dos LEDS, porque define, para além da percentagem dos componentes que NÃO mantêm as características de fluxo luminoso declaradas (B), até a percentagem de mortalidade do componente LED.

Taxa de imperfeição “F” = valor “B” + valor “C”

Exemplo:

Theos L90B10 @ 100.000 h

Entre anos (100.000 h @ 8 h / dia):

«L» => todos os LEDs mediamente terão 10% do fluxo deteriorado.

«B» => 10% dos LED terão mais de 10% do fluxo deteriorado (ou do valor indicado por L) ou não estarão mais funcionando.